產(chǎn)品詳情

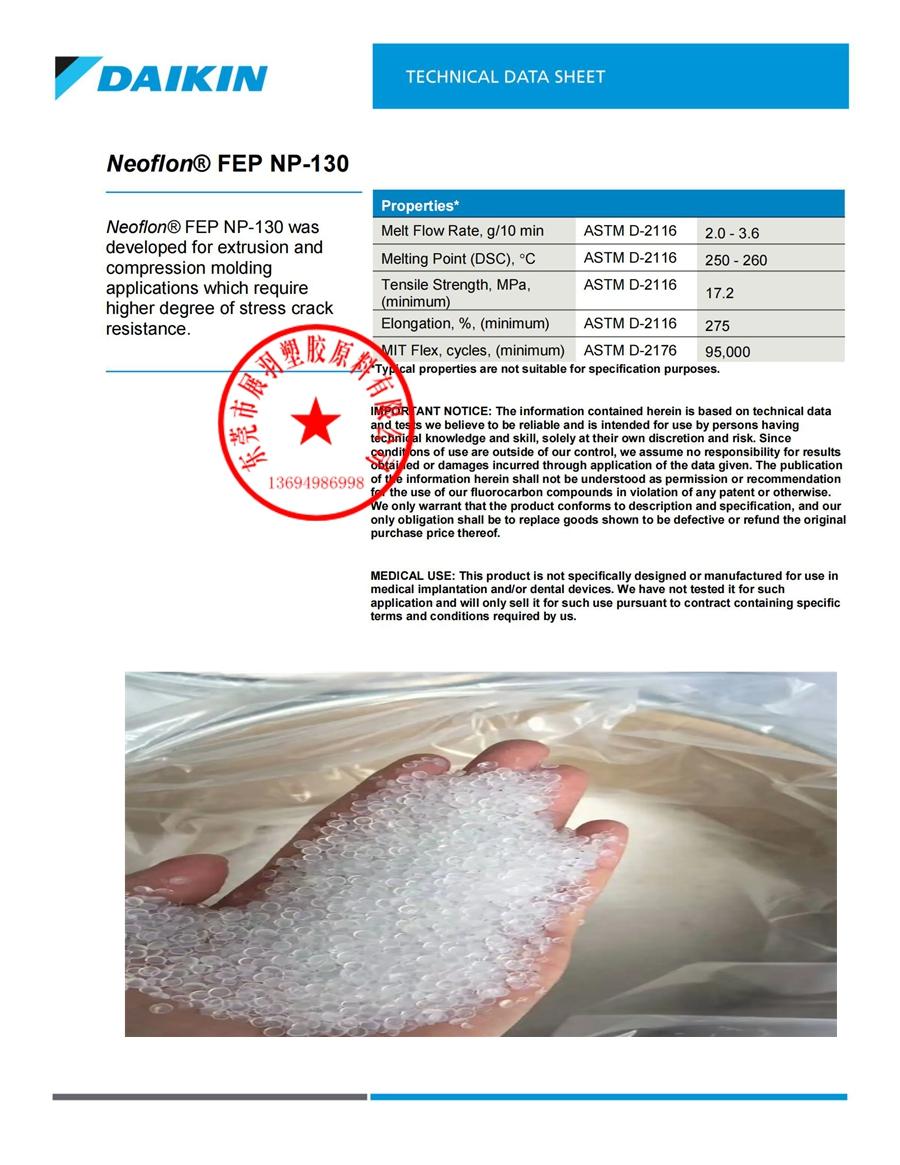

NEOFLON FEP NP-130 Daikin Fluorinated Ethylene Propylene copolymer

NEOFLON™ FEP NP-130 by Daikin is a perfluoroethylene propylene (FEP) copolymer of tetrafluoroethylene (TFE) and hexafluoropropylene (HFP). It exhibits high stress crack resistance, resistance to weather-, chemicals-, moisture-, light-, flame- and permeation. It provides low melt viscosity and high transparency. It shows non-sticking properties, electrical reliability, chemical stability, low reactivity, low critical surface energy, thermal- and chemical stability. It possesses good processability, low dielectric constant, dissipation factor with high dielectric strength over a wide range of frequencies and temperatures. It is suitable for sheet by extrusion process. It is recommended for thick wall wire & cable insulation, jacket and tubing. NEOFLON™ FEP NP-130 complies with FDA 21 CFR.177.1550, ISO 9001 (Quality System), ISO 14001 (Environmental System) and Responsible Care 14001 (Safety, Health, Environment and Security).

FEP Product Brochure

NP-20

NP-30

NP-40

NP-101

NP-102

NP-112

NP-120

NP-130

NP-1108

NP-1109

NP-3180

Daikin FEP (Fluorinated Ethylene Propylene copolymer) is a melt processible fluoropolymer. Although it is lower melting than PTFE, it still maintains a continuous service temperature of 200 Deg C. Because FEP is fully fluorinated like PTFE, it is extremely inert, has excellent electrical properties, high chemical stability, low friction, excellent long term weathering and very good low temperature properties. It is used in high speed wire insulation, cable jacketing, extruded film, blown film, sheet extrusion, tubing, heat shrinkable tubing, catheters, molded parts, and equipment and pipe linings. Daikin provides a wide range of melt flow indexes to choose from, as well as standard copolymer grades and modified copolymer grades that have improved mechanical properties.